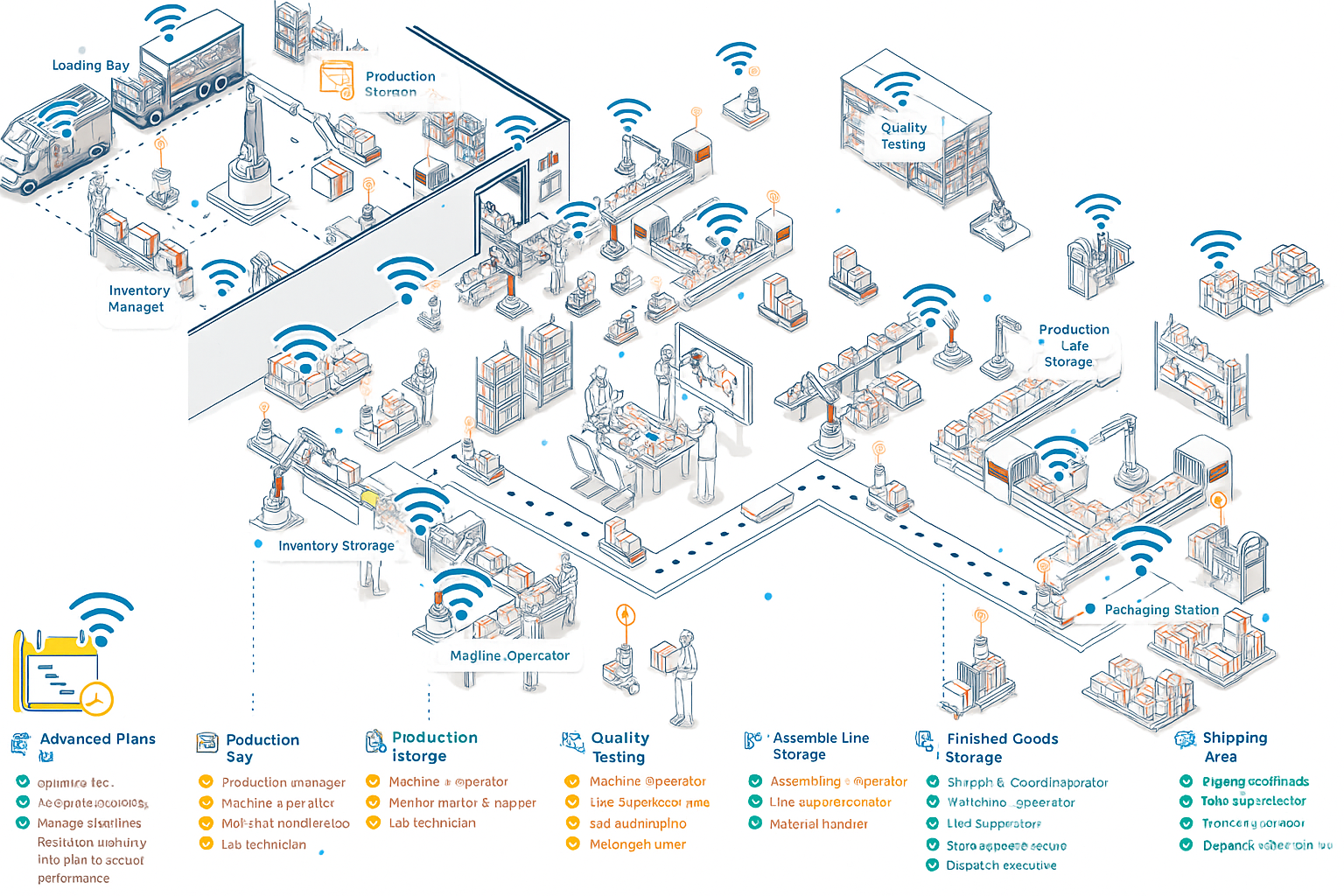

Powering the

Smart Factories

of Today and

Tomorrow.

Disconnected systems disrupt productivity - we bridge the gaps with seamless manufacturing solutions.

Can't

Monitor

Machines, Production

in Real Time

in Real Time

Making

Decisions in

the Dark

Spreadsheets, Manual Process

are showing up down

are showing up down

Mordern

factories

shouldn't rely on

outdated tools.

shouldn't rely on

outdated tools.

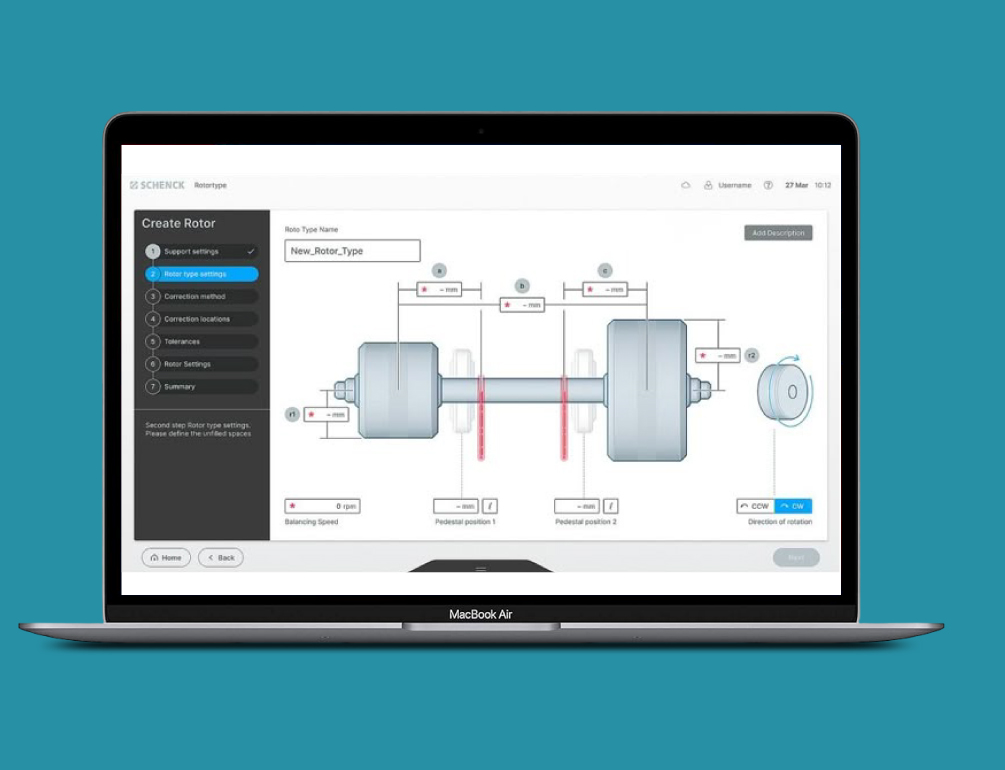

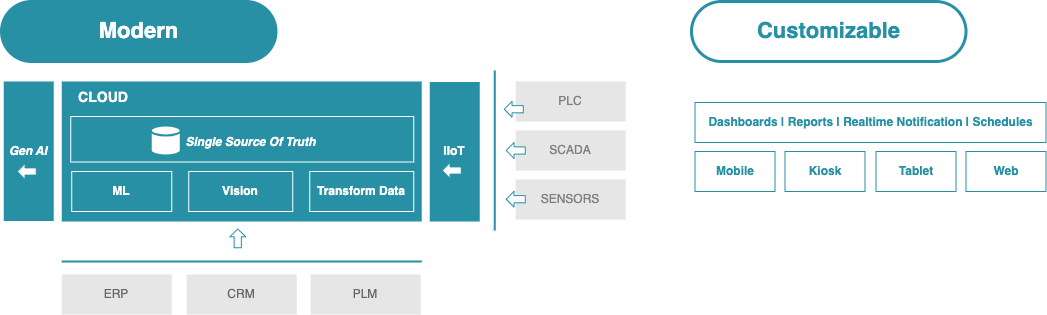

The Configurable Modern MES for Unique Factory needs

Modern Tech Stack and

80% Ready and 20% required for your uniquefactory needs

-toward clarity, speed, and confidence on your factory floor.

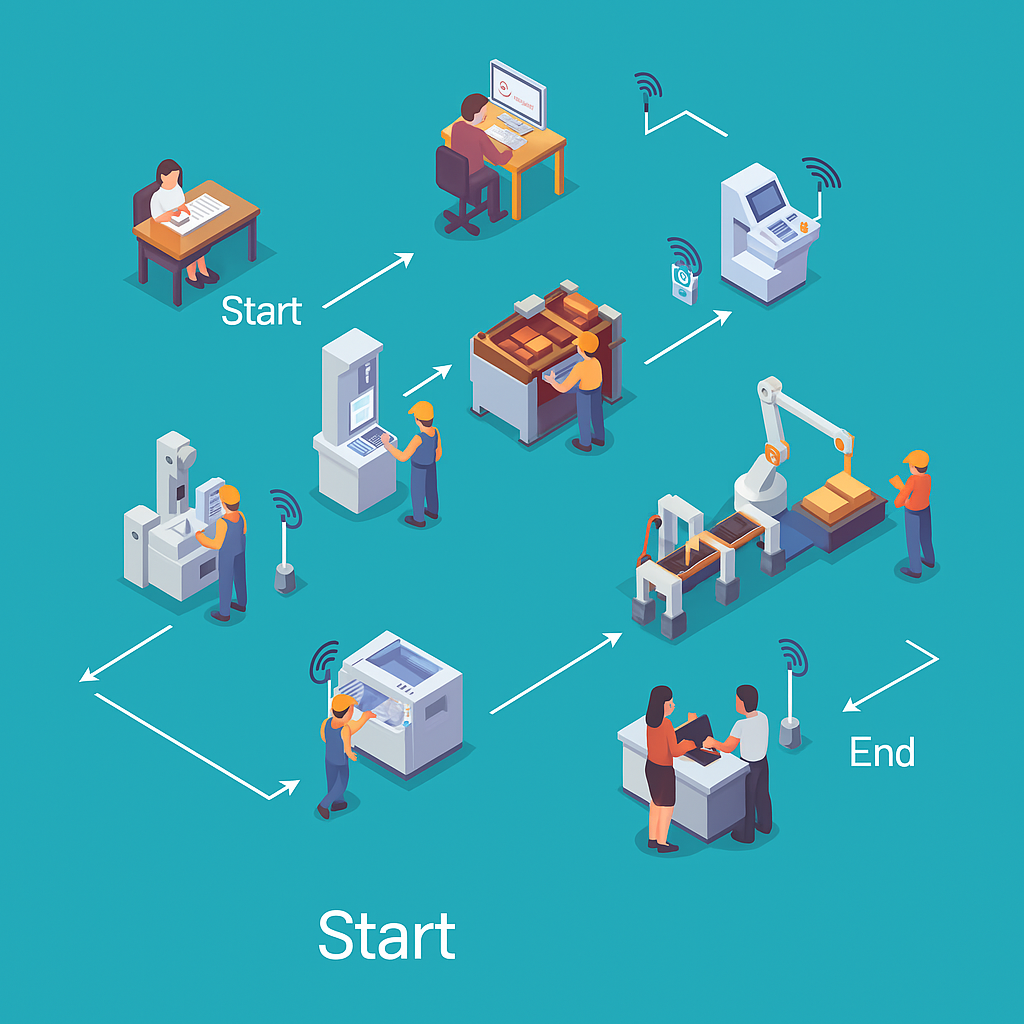

FactoryBOT is a modular Manufacturing Execution System (MES) built for modern manufacturers

FactoryBOT adapts to diverse manufacturing environments with industry-specific MES configurations.

Batch Manufacturing

Production in batches, each with specific quantities and traceability.

Discrete Manufacturing

Assembly of distinct items like appliances, or machinery

Job Shop Manufacturing

Low volume, high variety, made-to-order production

The Configurable Modern MES for Your Unique Factory

Customizable

Optimized for Your Factory: The 80/20 MES�80% Prebuilt, 20% Tailored for Precision.

Smart Integration: IIoT, PLC, Sensors, Dashboards.

Designed for Accessibility: Mobile, Tablets, Touch PCs.

Connected Ecosystem: ERP, CRM, Digital Checksheet.

Optimized for Your Factory: The 80/20 MES�80% Prebuilt, 20% Tailored for Precision.

Smart Integration: IIoT, PLC, Sensors, Dashboards.

Designed for Accessibility: Mobile, Tablets, Touch PCs.

Connected Ecosystem: ERP, CRM, Digital Checksheet.

MES

Modules

MES

Modules

Advanced Planning & Scheduling

(APS)

(APS)

Optimize orders, assign resources, and manage timelines.

Real-time

visibility into plan vs actual performance.

+

Production Tracking System

(PTS)

(PTS)

Track WIP, job status, and process stage-by-stage in

real-time

across departments.

+

Machine Management System

(MMS)

(MMS)

Monitor machine uptime, downtime, performance, and

enable

predictive maintenance with real-time alerts.

+

Quality Management System

(QMS)

(QMS)

Manage inspections, log defects, set sampling

strategies,

and

generate compliance-ready QC reports.

+

Workforce Management System

(WMS)

(WMS)

Assign roles, track operator performance, skill-mapping

and enable

accountability on the shop floor.

+

MES

Modules

MES

Modules

Advanced Planning & Scheduling

(APS)

(APS)

Optimize orders, assign resources, and manage timelines.

Real-time

visibility into plan vs actual performance.

+

Production Tracking System

(PTS)

(PTS)

Track WIP, job status, and process stage-by-stage in

real-time

across departments.

+

Machine Management System

(MMS)

(MMS)

Monitor machine uptime, downtime, performance, and

enable

predictive maintenance with real-time alerts.

+

Quality Management System

(QMS)

(QMS)

Manage inspections, log defects, set sampling

strategies,

and

generate compliance-ready QC reports.

+

Workforce Management System

(WMS)

(WMS)

Assign roles, track operator performance, skill-mapping

and enable

accountability on the shop floor.

+

Outdated tools slow down progress-modern factories need smarter solutions.

No Seamless Monitoring

Production, Machines, and Workforce Remain Untracked in Real Time.

Production, Machines, and Workforce Remain Untracked in Real Time.

Making Decisions in the dark

Are outdated processes holding your factory back? Manual workflows and spreadsheets create hidden inefficiencies.

Are outdated processes holding your factory back? Manual workflows and spreadsheets create hidden inefficiencies.

What happens when factories resist digital transformation?

What's the true cost of postponing your factory's digital transformation?

Persistent Issues:

- Production delays continue to escalate.

- Quality issues go undetected until it's too late.

- Equipment failures occur without warning.

- Critical insights remain hidden until problems arise.

- Valuable time is lost trying to sync disconnected data and teams.

The Lasting Impact:

- Climbing operational expenses

- Limited capacity to scale or expand

- Overburdened and demotivated teams

- Competitors gaining a clear advantage

- Missed orders and lost revenue opportunities

What Happens If You

Don't Transform?

We've seen this story before.

And we built FactoryBOT to change it.Let us guide you out of the old ways

-toward clarity, speed, and confidence on your factory floor.

What's the real price of delaying your factory's digital transformation?

Problems That

Persist

- Production delays pile up

- Quality issues go unnoticed

- Machines break without warning

- You have no visibility until it's too late

- You lose time trying to connects spreadsheets and people

The Deeper Cost

- Lost orders

- Stressed teams

- Rising operational costs

- No room to grow or scale

- The competition gets ahead

ENABLING SMART MANUFACTURING THROUGH ACCURATE DATA

-YOUR DIGITAL STRATEGY PARTNER:

.jpg)

1. Free Assessment

Get a complimentary evaluation

of your current

efforts. Identify

gaps, and wastages

+

.jpg)

2. Customize

Our expert team will give

recommendations tailored

to your unique

manufacturing needs. These insights are based on real data and industry best

practices.

+

.jpg)

3. Integrate

We guide you on the right

starting point to

maximize productivity.

+

.jpg)

4. Strategy Trail

Explore a roadmap of strategic

actions to reach

your goals. It's a

step-by-step guide to move from planning to performance.

+

.jpg)

5. Deploy

Turn strategy into results with

hands-on execution

support. We

help bring your vision to life with proven process.

+

.jpg)

6. Scale

Grow with Real time data, Automation and detailed

insights.

+